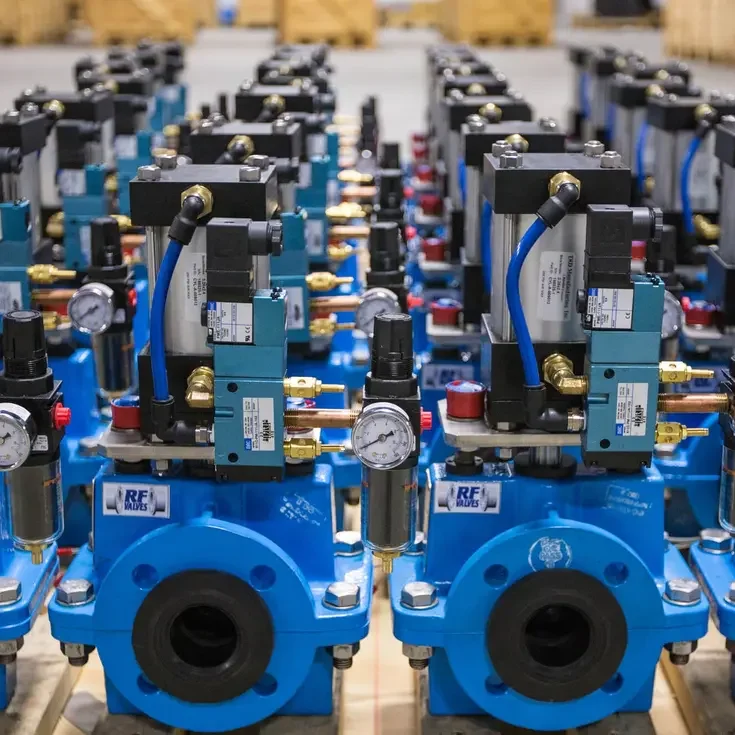

Pneumatic Pinch Valves

Our patented elastomer tube folds extend the life of your pinch valves for optimal durability and performance.

RF Valve Advantages & Key Features

- Robust and versatile actuators receptive of positioners of leading manufacturers

- Exterior as well as interior corrosion resistant Fusion Bonded Epoxy Powdercoating

- In-line and quick tube change with patented tube folds for durability & self-cleaning

- Standard Face-to-Face

Available Configurations

- CONTROL – MODULATING (Sizing available)

- ISOLATION – ON/OFF

Brands:

Pneumatic

Pneumatic Pneumatic Valves

Pneumatic Valves MONSYS BOX - Smart Valve Wear Sensor System

MONSYS BOX - Smart Valve Wear Sensor System- Maintenance - In-line Tube Replacement (Spanish)

- Maintenance - In-line Tube Replacement

RF Pneumatic

RF Pneumatic Tube

Tube- Pinch Valve Animation

Industries

Specifications

- Size Range1" (25mm) to 60" (1500mm)

- Temperature-50degF to 250degF

- Max. Working PressureUp to 300psi (20bar) (consult for higher pressures)

- Standard Face-to-FaceASME B-16.10, DIN 3202, ISO 5732

- Flange DrillingANSI 150#, ANSI 300#, DIN, JIS, AS

- ActuationDouble or Single acting pneumatic, Fail Open or Close

- Tube MaterialNR, PGR, EPDM, NBR, IIR, CR, FPM, CSM (View Chart)

- In-Line Tube ChangeYes

- Wear SensorYes, option

- Body TypeEnclosed or Sealed

- Body MaterialDuctile iron (CRN available) or aluminum

Downloads

Catalogs

RF Valve

https://www.rfvalve.com/sites/default/files/2012%20RF%20Valve%20Catalog%20%20English%20TB%200812%20%28small%29.pdf EnglishRF Valve Canada CRN

https://www.rfvalve.com/sites/default/files/2013%20RF%20Valve%20Catalog%20Canada%20CRN.pdf EnglishRF Valve Chinese

https://www.rfvalve.com/sites/default/files/2014%20RF%20Valve%20Catalog%20Chinese.pdf ChineseRF Valve Finnish

https://www.rfvalve.com/sites/default/files/2015%20RF%20Valve%20Catalog%20Finnish.pdf FinnishRF Valve Japanese

https://www.rfvalve.com/sites/default/files/2008%20RF%20Valve%20Catalog%20%20Japanese.pdf JapaneseRF Valve Russian

https://www.rfvalve.com/sites/default/files/2012%20RF%20Valve%20Catalog%20Russian.pdf RussianRF Valve Spanish

https://www.rfvalve.com/sites/default/files/2012%20RF%20Valve%20Catalog%20Spanish%20TB%200812%20%28sml%29.pdf SpanishRF Valve Spanish

https://www.rfvalve.com/sites/default/files/2012%20RF%20Valve%20Catalog%20Spanish%20TB%200812.pdf SpanishTri-Fold - All Product Lines

https://www.rfvalve.com/sites/default/files/RF%20-%20ALL%20LINES%20TRIFOLD.pdf English

Certificates

RF Valves Inc. HSB Global Standards

https://www.rfvalve.com/sites/default/files/RF%20HSB%20Global%20Standards%20Certificate%202016_0.pdf EnglishRF VALVES OY DNV

https://www.rfvalve.com/sites/default/files/DNV%2012%20ATEX%2012511Q%20RF%20VALVES%20OY.pdf EnglishRF VALVES OY ISO 9001

https://www.rfvalve.com/sites/default/files/ISO%209001%20RF%20VALVES%20OY.pdf English

Installation, Operation & Maintenance Manuals

RF VALVE Calibration IO&M Manual

https://www.rfvalve.com/sites/default/files/01%20Master%20IO%26M%20Manual%20MANUAL%20calibration.pdf EnglishRF VALVE Pneumatic Control Valve IO&M Manual

https://www.rfvalve.com/sites/default/files/03%20Master%20IO%26M%20Manual%20PNEUMATIC%20Control%20Valve.pdf EnglishRF VALVE Pneumatic IO&M Manual

https://www.rfvalve.com/sites/default/files/02%20IO%26M%20Manual%20PNEUMATIC%202014.pdf EnglishRFVALVE Pneumatic W-Mechanical Spring IO&M Manual

https://www.rfvalve.com/sites/default/files/04%20Master%20IO%26M%20Manual%20PNEUMATIC%20W-MECHANICAL%20SPRING.pdf English

Technical

RF Valve aiRFlex and Tube Technical Markings

https://www.rfvalve.com/sites/default/files/RF%20Valve%20and%20Tube%20Technical%20Markings%2004-20-2015.pdf EnglishRF Valve aiRFlex Codigos de Las Valvulas e Informacion

https://www.rfvalve.com/sites/default/files/RF%20VALVE%20aiRFlex%20Codigos%20de%20Las%20Valvulas%20e%20Informacion%20Tecnica.%2007-2011.pdf SpanishRF Valve aiRFlex Elastomer Tube Qualities and Selection

https://www.rfvalve.com/sites/default/files/Elastomer.pdf EnglishRF Valves Valve Data Sheet Imperial

https://www.rfvalve.com/sites/default/files/RF%20VALVES%20-%20Valve%20Data%20Sheet%202013%20Imperial.pdf EnglishRF Valves Valve Data Sheet Metric

https://www.rfvalve.com/sites/default/files/RF%20VALVES%20-%20Valve%20Data%20Sheet%20V2%2014_2013_METRIC.pdf English

Engineering Specifications

RF Valve Pneumatic Fail - Close Air Spring (PRC)

https://www.rfvalve.com/sites/default/files/RF%20Valve%20Pnuematic%20Fail%20-%20Close%20Air%20Spring%20%28PRC%29%20Pinch%20Valve%20Specification.pdf EnglishRF Valve Pneumatic Fail - Close Mech Spring (PKC)

https://www.rfvalve.com/sites/default/files/RF%20Valve%20Pnuematic%20Fail%20-%20Close%20Mech%20Spring%20%28PKC%29%20Pinch%20Valve%20Specification.pdf EnglishRF Valve Pneumatic Fail - Open Air Spring (PRO)

https://www.rfvalve.com/sites/default/files/RF%20Valve%20Pnuematic%20Fail%20-%20Open%20Air%20Spring%20%28PRO%29%20Pinch%20Valve%20Specification.pdf EnglishRF Valve Pneumatic Fail - Open Mech Spring (PKO)

https://www.rfvalve.com/sites/default/files/RF%20Valve%20Pnuematic%20Fail%20-%20Open%20Mech%20Spring%20%28PKO%29%20Pinch%20Valve%20Specification.pdf EnglishRF Valve Pneumatic Pinch Valve

https://www.rfvalve.com/sites/default/files/RF%20Valve%20Pnuematic%20Pinch%20Valve%20Specification.pdf English

Accessories

- Actuator - Fail Positions - Fail Close/Open via Mechanical or Air Spring

- Actuator Lockout

- Manual Override

- Positioner - Electro-mechanic or pneumatic

- MONSYS Box - Smart Valve Wear Sensor System

- Junction Box

- Gauges

- Limit Switches - Proximity, Mechanical or Magnetic

- Pressure Switch

- Filter/Regulator

- Solenoid

- Opening Tags

- Elastomer Tube Options - wear sensor wire or reduced port